Description

Introduction

Galvalume is steel coil with a lamination of Al-zinc alloy. Currently, 15-25% Al-zinc is most widely used in ppgi manufacture. In Jianglin, we are one of the leading manufacture of Al Zn billet.

With the different factory requirement, Al-zinc alloy formula can be different, which can increase the galvaluming process meanwhile, reduce the chance for stopping the production line.

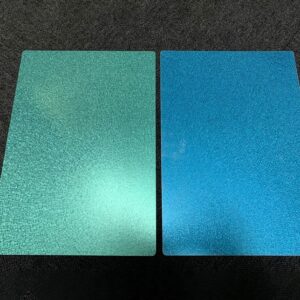

Surface compare

|

|

Surface in Detail

|

|

Compared with 55% Aluzinc(the spangle is more dimensional, the edge is more clear)

|

|

TECHNICAL TERM FOR KOREAN MARKET

The Basic Parameters

| Grade | DC51D+AZ, DC53D+AZ, S250GD+AZ,S300GD+AZ, S350GD+AZ, S550GD+AZ |

| Thickness(mm) | 0.16mm-2.5mm |

| Width(mm) | 600mm-1250mm |

| Inside Diameter(mm) | 508/610mm |

| Outside Diameter(mm) | 2000mm |

| Weight | ≤25ton per coil |

| Spangle | regular spangle, small spangle, big spangle |

| Surface Treatment | chromated, oil, Chemical treatment and oil, dry, anti-finger print |

| Aluzinc thickness | 30/30, 40/40, 50/50, 60/60, 75/75, 90/90, 110/110 |

Comparison between Galvanized coil and Galvalume coil

1. Coating type

Aluzinc coating is 55% Al-zinc content, Galvanized coil is pure zinc.

Aluzinc coil can have better anti corrosive ability, based on research.

2. Better production efficiency

For producing Galvanized coil, the furnace need be higher temperature than Galvalume coils. When producing Galvanized coil, the furnace need twice cleaning process at least each month. However, when producing galvalume coil, there is less chance for cleaning the furnace, which can save factory much cost.

Application Guidance:

DC51D+AZ and DC52D+AZ are mainly used for normal cold processing , most widely commercial products including home appliance, furniture. S250GD, S300GD, S350GD, S550GD are mainly used for structure, or construction.